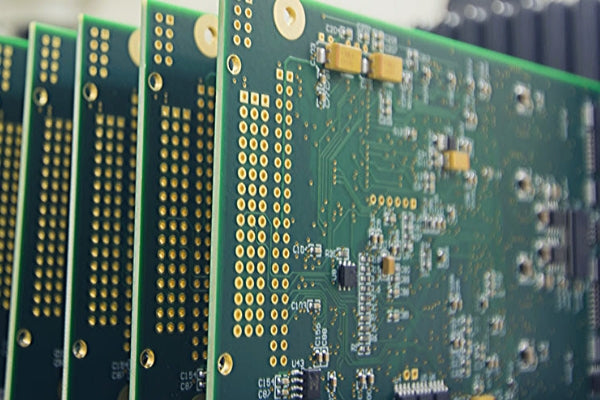

Humidity and heat are a cause of trouble in working and controlling of electronics in machines.

Humidity is an adversary of joint parts in electronics that are integral in controlling machines.

It is known that corrosion grows swiftly when humidity rises above 60%, varying levels of humidity and temperature also make electronics vulnerable. Controlling humidity and temperature levels must be observed for smooth functioning of electronic equipments.

Humidity contributes to corrosion by the process of Ion migration.

When voltage is applied to the metal in electronic equipments, the water molecules from the air (humidity) that have settled onto the metal surface causes the metal ions to elute. This is known as ion migration.

When ions migrates, there is a risk of short circuit due to the adjoining conductor metal.

In a lot of cases, circuits burn when large current comes in contact of conductor flowing causing non-regeneration.

The process of corrosion :

Step 1 : Water molecules (humidity) in the air condenses on metal surface.

Step 2 : Voltage is applied to this metal surface and it starts eluting as metal ions.

Step 3 : Eluted metal ions are then picked by nearby conductors.

Step 4 : Metal film serves as a link between the conductors, causing short circuit resulting in breakdown of electronic devices.

*Metal films are brittle and are in dendrite shape hence they usually evaporate at the time of short circuit. Therefore, failures caused by ion migration are not regenerated after its occurrence.

Share:

Dehumidifiers for Manufacturing Areas.

Dehumidifiers for Food Industry.