Application Areas

- Hotels & Resorts

- Defence

- Pharmaceuticals

- Hospitals

- Eye Hospitals

- Food Industry

- Chocolate & Sweets

- Spices & Powders

- Server Room

- Electronics Industry

- Warehousing

- Museums & Art Galleries

- Archives & Libraries

- Printing

- Diamond Laser Machines

- Laboratories

- Indoor Swimming Pools

- Gym & Yoga Centers

- Spas & Salons

Our Clients

Dehumidifiers for Hotels and Resorts

Humidity impacts guest experience in hotels in the form of musty smelling rooms and air feeling heavy to breathe easily. Humidity also discolors walls, dulls furniture, breaks down electronics adding to maintenance woes.

Dehumidifiers regulates humidity to keep fungal growth out ensuring no musty odour, easy breathing for guests and newly looking rooms and assets.While buying guest room dehumidifiers certain factors are to be considered as the idea is to provide enhance guests experience during the time of visit. These room dehumidifiers need to be extremely silent, easy to move and should have a sophisticated sleek look that goes well with the interiors.

Problems Faced

Sweating Walls

Walls and ceilings of guest rooms in hotels and resorts experience condensation due to temperature differential between the outside and inside. The sweating in the guest rooms lead to fungal growth, black spots, and also damages the electronics, upholstery, carpets and wooden furnishing. Sweating also leaves behind a musty odour in guest rooms.

Black Spots

Over time, water droplets on walls & ceilings of hotels and resorts turn into fuzzy black dots, which is a form of fungal growth that spoils the decor of the room, resulting in musty odor, refurbishing the guest room is an expensive and time-consuming and it also impacts the revenue of the hotel due to the unavailability of guest rooms.

Musty Odour

Due to trapped moisture in guest rooms, fungus develops on carpets, curtains and linen leaving an unpleasant musty odour and poor customer experience.

Electronic Failures

Electronic equipments installed in hotels like LED / LCD TV, DVD players, gaming devices tend to malfunction due to condensing of humidity on the electronic parts.

Discoloration

The newly done up hotels or guestrooms will start looking faded with moisture discoloring the paints, upholstery, artifacts and furniture polish.

Energy Cost

Restaurants, Spas, Gymnasiums use up too much energy in the form of air conditioning or treated fresh air during non operational hours to keep humidity at check, a dehumidifier can do the job at 1/10th the operational cost. If you consider the Total cost of Ownership, dehumidifiers pay off their cost in less than a year, besides saving the valuables in guest rooms.

Application Areas

Guest Rooms

Bed rooms, Living areas, Walk in wardrobes, Kitchenette.

Common Areas

Spas, Indoor swimming pool, Gymnasium, Ayurvedic massage areas, Corridors, Kitchen.

Storage or Housekeeping

Linen, Grains, Spices, Snacks, Stationary.

Customer Speak

Dehumidifiers were not working. Ms. Khushbu was very professional and a good team. Good follow up and quick service.

Shomik Dasgupta, Assistant Engineer @ Taj President

No more musty smell with Origin dehumidifier.

Ms. Sonali Sali (Purchase Manager) | Ms. Anagha Phadnis (Executive Housekeeper) @ Taj Wellington Mews

Dehumidifiers for Defence

Equipments used by the defense are very vulnerable to damage caused by moisture - everything from tanks, aircraft, ships, weapons and spare parts to the ammunition, optics, textiles and other equipment used and worn by military personnel become less serviceable and reliable.

Our metal body and roto-molded dehumidifiers are built strong to withstand tough environments and temperature and humidity.

Problems Faced

Corrosion

Most defense equipment utilize metal construction in aircrafts, aviation spare parts naval ships, submarines, etc. The biggest maintenance challenge is to protect it from excess humidity as it can corrode expensive equipment resulting in downtime and replacement costs.

Electronic malfunction

Electronic equipment in Radar rooms or Relay stations need to be protected from downtime, and a very frequent problem at remote installation is condensation damage inside equipment panels resulting in short circuit & failure of equipment. A dehumidified chamber can help prevent moisture related failures.

Ammunition failure

Ammunition is made up using explosive powders, and needs to be kept dry. Incase moisture seeps into this explosive material, it can result in misfiring / short firing that can cost the lives of our defense personnel.

Food & Staple store

Defense installations store & manage staple food such as grains, sugar, salt in Victualing Yard. These are generally stored for long duration and excess moisture can cause moisture damage.

Application Areas

Aviation, Electronics, Food Stores

Armament store (Missiles, explosives, etc)

Aircraft Simulator rooms

Radar room (Electric equipment's)

Meteorological equipment rooms

Server rooms

IT & Telecommunication rooms

Customer Speak

Portable Dehumidifiers are mission critical equipment used for a wide range of applications in Defense / Allied industries, such as in Air force or Naval stations for protecting expensive radars, missiles, training simulators, victualling yards, and even maintaining ambient RH inside of ships & submarine

Mr. Sudhir Damodara @ Climatronics Technologies Pvt. Ltd.

Dehumidifiers for Pharmaceutical Industry

Pharmaceuticals, nutraceuticals in the form of powders and granules are very hygroscopic in nature.

While production of such capsules and tablets, moisture present in the air and excess humidity result in agglomeration, uneven distribution of ingredients, bacterial contamination which leads to inefficiency and downtime.

Dehumidifiers maintain ideal humidity level and a dry environment which prevents degradation, ensures safe and hygienic storage conditions and reduced rejects.

Every stage in the pharma industry right from production areas, powder rooms , packaging areas to storage rooms require moisture and humidity control to meet the high quality and production standards that have been set. High humidity leads to agglomeration and triggers growth of bacteria, mold and yeast. Leading pharma companies have adopted GMP practises of maintaining optimum humidity.

Problems Faced

Agglomeration

Pharmaceutical ingredients used in powder rooms are hygroscopic in nature. n case of high humidity they clump together, technically called agglomeration; this can lead to blockages in the processing equipment & bacteria formation in final product.

Raw material deterioration

Pharma products utilize formulations in various forms – powder, liquid or premix and they are extremely hygroscopic. Moisture can reduce the pharmacological activity of the compound.

Bacterial contamination

Bacteria / Fungal growth can occur due to high moisture content in storage areas of pharma ingredients, and this can result in product recall & loss of reputation for the company.

USFDA / EU compliance

Pharma Industry is one of the few regulated industries with very stringent standards and standard operating procedures (SOP’s) and companies operating in this sector are expected to maintain temperature, relative humidity & clean room standards.

Application Areas

Lab scale development (pilot scale)

Lab scale development entails piloting of the actual plant with the same ambient condition, portable dehumidifiers are a good option in small prototype rooms. powder flow and behaviour is proportianate to the humidity maintained in the powder room.

Storage of powders and liquids in Powder rooms

Fine powder absorbs moisture which leads to inconsistency and clogging, thus affecting the product quality. Moisture levels in powder rooms have to be controlled in order to maintain their quality and efficiency.

Product Mixing

Product Mixing

Product Drying

Product Drying

Tablet Compression

Powder compression is done in dry state. Excess moisture causes caking and lumping, reduces medicinal effectives and leads to inadequacy in tablet process

Sugar Coating

To prevent build up of residual moisture during sugar coating process it is extremely necessary to emphasize on adequate drying conditions in the process.

Film coating

Films coated on capsules are hygroscopic and can lose it's texture and colour due to excess humidity

Packing material storage – CFB (staking strength) / Foil (rust)

To avoid moisture regain and to ensure vitality of the product throughout its shelf life

Storage of intermediate / finished products

Ideal environment conditions in pharma storage rooms is crucial to safeguard the effectiveness of medications within them. In certain cases temperature and humidity fluctuations have lead to degeneration.

Pharmaceutical are known to have the most Intense Impact on them due to High Humidity. Impacts can be listed below

Powders in powder rooms clump together and cause blockages in pneumatic transport systems.

Provide conditions for bacterial growth.

Greater risk of bacterial growth.

Reduced product and coating quality.

Reduced product shelf life.

Reduced productivity due to inefficiency and downtime.

Result in an uneven distribution of the active substances in powders.

Result in uneven surfaces when coating.

Problems with packaging processes.

The performance of active substances can be affected.

Ideal humidity level for all the pharmaceuticals should be between 40%-55% RH

The only way to get rid of these problems is to remove high water content from air using dehumidifiers.

Know the Various Applications!!

Powder Rooms

Tablet Compression.

Research & Development Lab.

Capsule Packing.

Formulations lab. And many more...

Customer Speak

We are using Origin dehumidifier in our Archival Room to preserve quality of important documents and are happy with it. We also appreciate Origin's after sales service.

Ms. Ruchira Jackson (Assistant Manager, Quality Assurance) @ Glenmark Pharma

Origin dehumidifier is working satisfactory since last 5 years. It maintains humidity in limit. Service given by Origin is OK.

Mr. Narvekar @ J. B. Chemicals and Pharmaceuticals

We need to maintain humidity at 50% in our lab and are able to maintain it with Origin dehumidifier.

Mr. Raghavendra Rao @ Euroslot Kdss India Pvt .Ltd.

Using Aerial and Novita dehumidifiers for R & D. We use in the process where from Tablet, Capsules and powder, water contain determination is being done. We also use for the application of weighing standards and in Bioanalytical department for analyzing bio samples. We thank Mrunmayee for recommending appropriate dehumidifiers which helped us to keep the RH in control.

Swapnil Kharage @ Sun Pharma

Dehumidifiers for Hospitals

Humidity is one of the factors that contribute to safe and sterile environment in healthcare facilities.

Excess humidity is known to make the environment uncomfortable for patients and cause structural damage to expensive healthcare equipments and lenses. Dehumidifiers have proven to be ideal solutions to meet the stringent humidity requirements in hospital areas as per international standards.

Problems Faced

Damage to lenses in Lasik

Eye Hospitals use Lasik equipment comprising of high power lenses, which can get damaged, incase of condensation on active lenses. This results in auto shut down of equipment incase humidity exceeds 65% RH.

Condensation in Imaging Areas

Medical imaging equipment have revolutionized healthcare diagnosis and healthcare, but these expensive equipment – MRI / CT machines require low temperature & humidity to be maintained 24*7 to prevent condensation damage.

X-Ray film damage

X-ray film requires to be stored in ambient humidity conditions, else there is a likely photo-catalytic reaction on this which could lead to poor image quality. This can result in improper diagnosis / cure for patients.

Application Areas

CT Scan, PET-CT, Cath Lab, MRI, Mammography, Eye O.T, Lasik, Radiation / Oncology, X-ray.

Customer Speak

Deviation, wrong readings, and repeated break downs in our healthcare machinery have been significantly reduced by Origin dehumidifiers.

Mr. Prasad @ Hinduja Hospital

I am equally satisfied with the performance of Origin dehumidifier and their service support.

Dr. M. I. Doongerwala @ Eye Surgeon

As a doctor I also recommend the use of dehumidifiers for people who suffer from respiratory related diseases.

Dr. Ashwin Correa (DNB, DMRD, DMRE) @ Ashwin Diagnostic Centre

Excellent service by Origin. Dehumidifier machine maintains the required RH condition for the expensive instruments. It's a useful machine.

Dr. Goyal @ Surya Eye Clinic

I am using the dehumidifier in the OT. Mrunmayee had explained about the usage of dehumidifier very well. The explanation given at time of installation of the dehumidifier was valuable. My experience with Mrunmayee was excellent. She is very knowledgeable.

Dr. Sunil Jain @ Iris Eye Clinic

Dehumidifiers for Eye Hospitals

Moisture damage can occur in several forms – visible & invisible. Visible damage includes spotting on optical lenses, fungal growth, etc. Invisible moisture damage is primarily condensation that occurs on cold surfaces that can increase the chances of moisture related malfunction. Since, latest medical diagnostic equipment’s are today made up of advanced electronics – an additional layer of protection is imperative.

Moisture damage can occur in several forms – visible & invisible. Visible damage includes spotting on optical lenses, fungal growth, etc. Invisible moisture damage is primarily condensation that occurs on cold surfaces that can increase the chances of moisture related malfunction. Since, latest medical diagnostic equipment’s are today made up of advanced electronics – an additional layer of protection is imperative.

Eye Hospitals use dehumidifiers in various areas – primary of these are

- Lasik Operation Theatres

- Patient acclimatization area

- Optical equipment protection

Lasik operation theatres need portable dehumidifiers to have a consistent and accurate RH levels to prevent moisture from settling on the high power lenses of laser machines. Optical equipment used by Ophthalmologists are made of fine & precise lenses – these lenses grow fungus, spots unless the same is placed in low / controlled humidity. A portable dehumidifier is the most practical method to maintain controlled humidity – thus providing a layer of safety for all your valuable equipment and an effective way of protecting it from moisture damage.

Dehumidifiers for Food Industry

Food production, processing, packaging and storage facilities require good hygiene — controlled and consistent.

Excess humidity causes bacterial growth, condensation on cold products, damaging packaging and spoiling the product resulting in poor consumer experience.

Refrigerant dehumidifiers are the most efficacious and cost-effective way to reduce levels of moisture in the air and maintain desired humidity level to optimize the quality of food products.

Keeping the production, processing and storage facility clean also means keeping humidity regulated as it improves hygiene. Hygiene is critical in all areas of food production and processing. To meet these standards it has become extremely important to observe stringent humidity and temperature controls right from production, processing and storage areas to the packaging rooms of food products.

Problems Faced

Hygroscopic Powders

In production and packaging units of hygroscopic powders like pre mixes of cocoa, tea, soup absorb humidity easily and clump together, technically called agglomeration; this can lead to blockages in the processing equipment & bacteria formation in the final product.

Chocolates

Cocoa powder tends to absorb moisture easily and can hamper the quality of the chocolate. Those chocolates stored in uncontrolled RH areas can attract bacteria and worms thus resulting in large scale loss of reputation & damages.

Bacterial contamination

Several types of bacterial growth can occur in food, since they are a high nutrient media for bacteria such as E.coli or Streptococcus (commonly found harmful bacteria).

Crispy snacks

Ready to eat snacks, breakfast cereals, are generally crisp and need to be maintained in low RH atmosphere – else they tend to absorb moisture and lose their crispiness and become unappetizing , resulting in poor consumer experience.

Bad odour

High humidity leads to fungal growth which releases a musty odour, which can transfer to food products. Controlled humidity can help maintain quality products round the year without worries about sensory deterioration.

Application Areas

Food Production

Pre mixes, Ready to eat snacks, Chocolates, Bakery products, Confectionary, Dairy Products.

Food Storage

Grains & Grocery, Dry Fruits, Cocoa Tea and Coffee, Jaggery, Snacks, Biscuits.

Laboratories

Food testing labs, Product development.

Customer Speak

We are using Origin dehumidifier in our popcorn manufacturing unit. It removes excess moisture from air and makes our popcorn crisp and dry. With Origin dehumidifier, the quality of popcorn has improved.

Mr. Rajesh Rane (Senior Manager Purchase) @ Wow Popcorns

Mr. Ravi was very prompt to provide service and took effort to visit us at 7.45pm to ensure our work did not get hampered.

Ashish Agarwal @ Gold Tree Nuts - Food Industry

We use the dehumidifier in the Final Packing hall temperature maintained at 12 Deg C. and the ANTE room before the cold storage Dehumidifier prevents Moisture droplet formation on walls and ceilings there by: 1) Increasing the life of the metal Insulated Panels 2) Prevents bacterial slime formation on walls and ceilings which is very dangerous for food Industry. 3) Increases food safety by removing cross contamination by water droplets falling from ceiling onto packing table. 4)Increases life of electrical machinery used in the hall in such cold places where moisture can damage electrical circuits. We are very happy with Origin for their prompt action when we face problems as well as good after sales service. Mr Sudhir Damodara as well as Mrs. Preeti Rathi have always been very prompt, professional and customer oriented in their approach towards Jinny Marine and on a few occasions have gone beyond the call of duty to make us feel happy with Origin.

@ Food Industry

Using Aerial and Novita dehumidifiers for R & D. We use in the process where from Tablet, Capsules and powder, water contain determination is being done. We also use for the application of weighing standards and in Bioanalytical department for analyzing bio samples. We thank Mrunmayee for recommending appropriate dehumidifiers which helped us to keep the RH in control.

Swapnil Kharage @ Sun Pharma

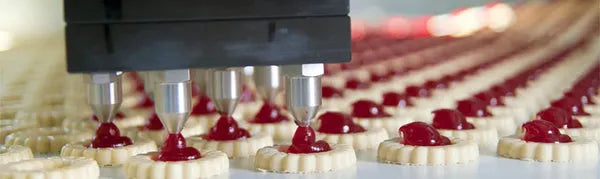

Dehumidifiers for Chocolates, Sweets and Confectioneries

Sugar a main ingredient in sweets, mithais, chocolates, candies tends to get sticky in a high humidity environment.

This results in:

- Poor product quality, shorter shelf life and poor consumer experience

- Storage, packaging and product challenges

- Clumping of powder resulting in production delays and rising operating cost

- Hygiene conditions will be compromised

- CONTROLLED HUMIDITY levels are very important to enhance production, improve hygiene and meet the quality standards in each step right from production to packaging and storing of the items.

HUMIDITY CHALLENGES IN CONFECTIONERY PRODUCTION

India is hot and in some parts humid. Producing confectionary which is good and consistent in quality is critical to meet standards for a good consumer experience. The ingredients and the end products in confectionery manufacturing are easily effected by airborne moisture. Most of the ingredients are hygroscopic, and excess humidity impacts on just about every stage of confectionery production, packaging and storage.

A very common problem of moisture includes blooming in chocolates. "Blooming" happens when fat and sugar crystals rise to surface of the chocolate if the chocolate absorbs moisture during packaging.

Humidity also makes ingredients form lumps or lose their crispness like in nuts. This results in production delays, product rejection and more critically bacterial growth resulting in hygiene compromise.

Confectionery products require to maintain ranged relative humidity (and temperatures), and it’s very hard to achieve and maintain these by ventilation with uncontrolled air from outside.

PREVENTIVE ACTION – GETTING RID OF THE PROBLEM

Origin Dehumidifiers provide energy-efficient portable dehumidifier range which is suitable for production, processing, storage and packaging areas to ensure your sweets are consistently good and quality standards are met. Our dehumidifiers ensure ideal humidity conditions are maintained throughout the process ensuring hygienic conditions and a seamless production.

Dehumidifiers for Spices and Powders

Spices are the key ingredients to any food recipe, they are used for adding flavor and for preserving food. Producing fine quality spices involve different stages like drying, grinding, quality testing, packaging and storing. Spices are dried and powdered and as they are highly hygroscopic in nature, they tend to absorb moisture very quickly and become sticky. Moisture absorption in spices lead to microbial growth, causes them to form clumps, loose flavor and weight and even develop mold overtime which not only has an impact on quality but also doesn't match the quality standards and are not suitable for consumption.

Spices are the key ingredients to any food recipe, they are used for adding flavor and for preserving food. Producing fine quality spices involve different stages like drying, grinding, quality testing, packaging and storing. Spices are dried and powdered and as they are highly hygroscopic in nature, they tend to absorb moisture very quickly and become sticky. Moisture absorption in spices lead to microbial growth, causes them to form clumps, loose flavor and weight and even develop mold overtime which not only has an impact on quality but also doesn't match the quality standards and are not suitable for consumption.

Dehumidifiers for Server Rooms and Data Centers

Having monitored temperature and humidity levels is extremely important forserver rooms and data centers which ensures system reliability, uptime and longevity of equipments.

Excess humidity causes fungus that attacks machines, disk drives to fail which leads to loss of data, system failures, rust build up, corrosion, condensation in inside hardware causing short circuits and damage to sensitive components

"Humidity has to be regulated effectively to ensure operational security and stability of equipments.

Dehumidifiers are a reliable solution that maintain the said humidity levels at all times which prevents unexpected downtime, system and component failures thus saving on unplanned costs on repairs and replacements."

Maintaining relative humidity between 45 % - 55 % is recommended for optimal and consistent performance in server rooms and data centres.

Dehumidifiers for Electronics Manufacturing.

CIRCUIT BOARDS

Electronic circuit boards are susceptible to high levels of moisture.

- Electronic circuit boards are susceptible to high levels of moisture.

- Short circuits or operational glitches in electronics

- Product failure, higher warranty claims and poor customer experience

HOW DOES HUMIDITY IMPACT ELECTRONICS

When the relative humidity is at 60%, corrosion is active. As the electronic circuit boards operate with very small voltage, any minute corrosion can increase the electric resistance of the equipment, leading to operational glitches to product failures. Humidity condenses on electronics especially when there is a sudden drop or increase in temperature, leading to electronic short circuits and corrosion.

If the humidity is not checked in time at the storage or manufacturing point, electronics can fail at the end user point leading to product failure, poor brand experience and high cost of replacement and repairs.

AVOIDING CORROSION AND ELECTRONIC FAILURES DUE TO HUMIDITY

Physics states that if you maintain humidity at and lower than 45% and if the quality of air is clean, its impossible for corrosion to take place.

Origin dehumidifiers have been used in storage and production areas to enhance the reliability of the electronic components and to protecting sensitive electronics from excess and varying humidity levels. Our portable dehumidifiers maintain ideal and consistent humidity levels and prevent corrosion, condensation and electronic circuit failures. Origin dehumidifiers are portable and robust and have proven to be an ideal solution in maintaining a controlled humidity environment to protect electronics from moisture damage.

Dehumidifiers for Warehouses

Humidity causes various a range of problems in storage areas such as damage to a vast range of structures, equipment, accessories, stocks and yes to the material stored in such warehouses.

Origin provides an exclusive range of dehumidifiers for large warehouses and stock rooms. Our dehumidifiers assure utmost reliability and cost saving using Blue dry technology and energy efficient compressors.

Problems Faced

Material Damage

Material stored in warehouses, storage area or packaging areas without RH control are susceptible to fungal growth, structural damage, discoloration or separation thus impacting the finished product quality. In order to prevent such damage to the product, it is recommended to maintain optimum humidity round the clock.

Contamination

Food and medicines in the storage area are at a risk of contamination since bacteria breeds in high humid areas, and uncontrolled humidity poses a major health hazard to consumers.

Discoloration

Paper & books tend to lose their original color and structure in high humidity resulting in wastage or poor quality. Storage areas need automated dehumidification system which runs 24/7 with humidity control systems to regulate the humidity in storage areas.

Structural damage

In high humid areas, most materials either adsorb or absorb moisture from atmosphere thus softening the structural matrix of stored products in the warehouse or the storage area; this can have wide ranging impact – from loss of strength to irreversible damage.

Separation

In high humid areas currency notes, foam material, plastic sheets tend to stick to each other, making separation difficult leading to product wastage.

Keeping a clean food production and storage facilities is not enough to keep consumables safe and increase their shelf lives. Food safety and quality is given the top priority in production areas.

To meet these standards it has become extremely important to observe stringent humidity and temperature controls right from production, processing and storage areas to the packaging rooms of the materials.

Application Areas

Electronic storage

Digital circuit boards, PCBs, Cameras, AV equipment, Electrodes.

Media storage

Magnetic Medias, Photographs, Optical Disc.

Currency storage

Strong room, Currency chest.

Musical Instruments

Piano, Harmonium, Guitar.

Material storage

Food, Soap, Upholstery, Metal – Umbrella, Furniture, Powder material, Packaging material – CFB / Foil / Laminates.

Know Why A Dehumidifier Is Necessary For Warehouses!!

A warehouse is a place where goods are stored for the purpose of moving them out at a particular time. Sometimes the storage time varies from short periods of a week to longer periods like months and years. Ware housings are employed to preserve the products in its original form. Excess moisture/humidity problems can easily occur in practically all kinds of warehouses and storage facilities, resulting in costly and trouble making damage to a wide range of goods and materials such as rubber mats, iron, powders, wood, cardboard, paper, salt, canvas, medicines, database logs etc and of course, to any products stored in such facilities. CLOSE

A warehouse is a place where goods are stored for the purpose of moving them out at a particular time. Sometimes the storage time varies from short periods of a week to longer periods like months and years. Ware housings are employed to preserve the products in its original form. Excess moisture/humidity problems can easily occur in practically all kinds of warehouses and storage facilities, resulting in costly and trouble making damage to a wide range of goods and materials such as rubber mats, iron, powders, wood, cardboard, paper, salt, canvas, medicines, database logs etc and of course, to any products stored in such facilities.

High ambient humidity inside the warehouse tends to deteriorate the product quality and its shelf-life. Often the products are placed one above the other in storage rooms. Products stored in this manner tend to fuse with each other. Typically high humidity inside the warehouses results in to sticking of the stored materials, deteriorating the chemical and physical properties of the product. The principle solution to this is the extraction of high water content from air. Ideal humidity level for all the store rooms in the storage area and packaging area should be between 45%-55% RH

High ambient humidity inside the warehouse tends to deteriorate the product quality and its shelf-life. Often the products are placed one above the other in storage rooms. Products stored in this manner tend to fuse with each other. Typically high humidity inside the warehouses results in to sticking of the stored materials, deteriorating the chemical and physical properties of the product. The principle solution to this is the extraction of high water content from air. Ideal humidity level for all the store rooms in the storage area and packaging area should be between 45%-55% RH

Know The Various Applications!!

- Electronic storage.

- Electrode storage.

- Semiconductor store.

- Currency storage.

- Document storage.

- Medicine Storage

- And many more….

Customer Speak

Mr. Sudhir who installed the dehumidifiers is a great person and knowledgeable about his work. We are glad with the results.

Rajendra Rathore @ G Shoes Export

I would like to thank Sudhir Paradkar for attending my call online and for offering very good support.

Pradip Shinde @ Shemaroo

We are using the dehumidifiers for shoe storage. Machines performance is good. Service is always available at doorstep. Mrunmayee's presentation, education about how to use the dehumidifiers was excellent. Her recommendation was right. After using Origin Dehumidifiers, we never had a problem of moisture and fungus. It helped us a lot in process of dispatch. I believe, Mrunmayee is the bright face of Origin. I will rate her 4.5 out of 5.

Mangesh Thorat (Admin Manager) @ Kavi's Fashion

Using it for garment storage..So far its good. It's a good machine. It's delivering results, and its a little early to comment about service but lets see :)

Mr. Deepak Wadhwani @ Garment Industry

Dehumidifiers for Museums and Art Galleries

Excess humidity in art galleries and museums cause damage to artifacts - paper based (books), canvas based (paintings) and leather based (clothing). It leads to condensation which causes corrosion, black spots or a yellowish tinge, discoloration and dullness which degrades the art value.

Dehumidifiers prove to be the most effective and economic way in maintaining the desired humidity level to protect and preserve your valued collection.

Problems Faced

Paintings

Due to excessive humidity and difference of temperature in the room and outside, condensation on the canvas can lead to fungal development and green/black spots on the painting eroding the look and the value of the painting.

Artifacts

Artifacts made of hard wood or stone tend to become brittle and develop a yellowish tinge in high humidity; metal and wooden artifacts develop black spots.

Galleries

Galleries are temporary exhibition halls where artists display their work for a few days or few weeks. High humidity can cause spotting & discoloration in paintings resulting in loss of value.

Archiving

Archiving is widespread across our country. India with its rich heritage has archives of music, literature, science, philosophy and more. All these books, tapes require an ideal RH (Relative Humidity) of 50% to ensure longevity and prevent deterioration.

Application Areas

Exhibit area

Paintings, Artifacts, Theaters.

Storage

Art, Artifacts, Books (Libraries), Musical Instruments.

Customer Speak

The Dehumidifiers have helped us to preserve our rare collection of artifacts, specially in the monsoons.

@ Bhau Daji Lad Museum

I use Origin dehumidifier to protect my collection of paintings.

@ Ms. Kajal Jain

Origin dehumidifier has protected my paintings.

Mr. Dilip Ghevariya @ Art Inteligo

Origin de-humidifiers are protecting our musical instruments from moisture. We also use them in our costume and guest rooms to keep musty odour out and keep the room clean and crisp.

Mr. Nayan Kale (GM Technical) @ NCPA

The performance and services in one word for me is 'Excellent'.

Prashant @ Shri Gurunani Nagkanya Yogini Trust

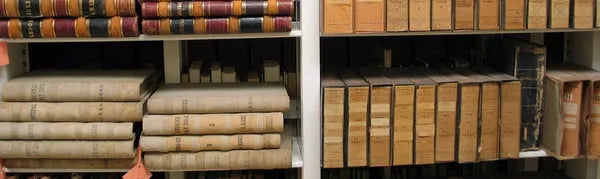

Dehumidifiers for Archives and Libraries

Archive rooms and libraries have records, documents and books which are susceptible to moisture damage and absorb moisture quickly which is why it demands a well-controlled indoor environment. Excess moisture levels have irreversible effects on the quality of documents, causes deterioration, develops a yellowish tinge on their surface and causes mold growth.

Dehumidifiers ensure controlled and consistent moisture levels which help a great deal in preserving and protecting the records and books from moisture damage. Dehumidifiers are a preventive measure for archives and libraries as they prevent moisture build up on the surface of records and books, thus preserving their quality and helping in prolonging their life.

Dehumidifiers for Printing Industry

Humidity plays a crucial role in the printing process, whether its textile printing, currency or any other secure press printing. There are standard temperature and humidity requirements that are to be met during printing and drying process to ensure product quality and safety of the expensive printing heads.

Refrigerant dehumidifiers have proven to be the most effective and economical solutions that get the desired humidity levels while printing, drying and packaging and storing.

Problems Faced

Drying time

Printing technology is moving towards faster and better printing techniques. In such a scenario, drying of ink plays an important role – and dehumidifiers help maintain a dry atmosphere which is conducive for high speed printing. In addition, dehumidifiers ensure that longevity of the expensive heads of the printing machine.

Condensation on CTP

CTP or Computer to plate uses computer directly to prepare draft plates rather than exposing them like earlier. These plates require both Temperature & Humidity control for maintaining quality parameters.

Currency / Cheque / Security Press Printing

High value printing machines require high quality output, and use mixed media which are machine readable, this means that print quality needs to be on highest quality material with clean & clear output. Lack of RH control can result in non-uniform output from them.

Digital printing machine

Digital Printing or Flex / Banner printing machines are very large & expensive, they are required to be housed in specialized rooms with RH control to prevent condensation damage & also help in quick drying of media.

Application Areas

CTP STORAGE

Computer to Plate

Security Printing

ID Card, PAN card

Bill printing

Currency notes, etc.

Digital printing

Banners, Flex, etc.

Nuclear research

IGCAR, Kalpakkam

Laminate printing

CFB Box printing

Professional use of dehumidifiers IN TEXTILE PRINTING

Excess moisture deteriorates textile printing quality, reduces elasticity and tensile strength of certain fabrics, causes machine damage and slows down the production and drying process.

Why Dehumidifier for textile printing?

Ideal humidity level when maintained for textile printing curtails yarn breakage in the weaving process, reduce downtimes and loom marks in the finished product. It upholds yarn strength and elasticity thus ensuring quality production and less wastage. Controlled humidity levels during textile printing contribute extensively in meeting quality standards, getting equipments to their optimum use, preventing mold & mildew which might stain textiles, reduced rejects.

Know Why A Dehumidifier Is Necessary For Printing Press!!

Best Printing is at Comfortable Conditions. The moisture content of a print shop is measured as relative humidity and it affects the amount of moisture in paper. Different printing processes work best with certain amounts of moisture. In digital printing the moisture content can affect the toner adhesion, paper jams and the fuser roller temperature. READ MORE

In offset it can affect the interaction between the ink and the press, the paper and the press, and the ink and paper. Inkjet is affected by many of the same issues but is even more susceptible to dot gain or ink spreading, drying delays and ink show. In the best conditions the paper is designed to be stable in a 45-55% relative humidity (RH) at 72°F environment.

Dehumidifier is a device specially designed for removing the extra water content from air and lower down the humidity level. Employing dehumidifier for your printing press will ensure perfect printing results on the sheets.

Know The Various Applications!!

- Computer to plate storage

- Specialized Printing.

- Production Areas

- Circuit Board Printing.

- Mass Bill Printing.

- And many more….

Customer Speak

With Origin dehumidifiers, smooth functioning of our digital printing machines is ensured.

Ms. Ruchira Nighojkar (Manager HR & Admin) | Mr. Santosh Kumbhar (Floor Manager) @ Jasraj Printing

We are into printing on T-shirts. We used to face problem of very fine spots on T-shirts while printing because of the moisture. Now with the use of Origin Dehumidifier, this problem is minimized. I am pretty happy with it.

Mr. Mushtaq @ Sportiff T-Shirt Printing

Dehumidifiers for Diamond Laser Machines

Laser machine consists of an optic screen on which the laser beams are bombarded. All these laser beams are focused on a single target by the optic screen. Diamond is placed on this target where it is cut and transformed in to glittering diamond. These laser machines are operated in air-conditioning areas and are maintained in the temperature range between 22-24˚c for optimum use.

PROBLEMS

In the non-working hours, when the air-conditioners are switched off, room temperature rises due to which condensation is experienced on all the possible surfaces including OPTIC SCREENS of laser machines. If this condensation on optic screen is not taken care of, it tends to leave moisture spots on the screen, deteriorating its quality. When laser beams passes over these spots on optic screen, it develops permanent spots on the screen. These laser beams passing through the screen are not at its optimal performance level. Consequently diamond cut is also affected.

ORIGIN'S SOLUTION

Origin Dehumidifiers extract the desired water content from air and blows dry air back in to the room and maintains ideal and consistent humidity levels. Our dehumidifiers ensure prevent condensation on surface of the lenses or any kind of humidity damage to the laser machine thus elevating its performance. Ideal humidity for laser machines is between 40-50% RH. Portable dehumidifiers from Origin have been installed at various diamond labs and has proven to be an ideal solution in maintaining controlled humidity levels thus protecting laser machines from moisture damage.

Dehumidifiers for Research and Development

Functioning and measurement of material and products are tested in research and development labs.

Environmental conditions affect measurement device characteristics and performance, hence research and development labs have stringent temperature and humidity requirements that need to be met.

Excess moisture causes structural damage to expensive equipment's and increases downtime. Refrigerant dehumidifiers have proven to be the most efficacious and effective solution that maintain humidity level at all times.

Problems Faced

Testing standards

Research and Development laboratories, commonly known as R&D lab needs to comply with testing standards such as ISO/IS/NABL/EU/ASHRAE and compliance requires maintaining humidity levels between 40 to 60% RH in the lab.

Condensation inside equipment

Most Research and Development equipments are placed inside the lab with controlled temperature and humidity. Humidity tends to damage equipments such as FTIR, ICP, etc. and any damage to powerhouse / crucial electronic sensors inside the equipment can cost heavily in addition to downtime.

Product Testing labs

Product development of cosmetics is based on consumer research & studies of human reception based on several months of research. During this stage of the research and development of the products, it is critical to maintain the relative humidity & temperature to ensure accurate results.

Laser studies

Many disciplines of science including Opto-electronics, Physics & Material Sciences study lasers using optical lenses. During these experiments, high moisture atmosphere in the lab can reduce the diffraction clarity & result in erroneous experiments. A dehumidifier maintains the right humidity in the research and development lab to ensure consistent performance of optical equipments.

Application Areas

Optical equipment

FTIR, ICP, Lens storage

Product testing lab

Cement / food / cosmetics

Pharma pilot scale

API testing

Laser equipments

BARC, TIFR

Nuclear research

IGCAR, Kalpakkam

Radio Transmission equipment

ISRO

Customer Speak

I am using Origin ND 290-i for reducing humidity in the microscopy room in my lab at IIT Bombay, Powai,. Because of excessive humidity in Mumbai weather, our microscope lenses used to get fungal contamination. After using this dehumidifier, we haven't faced this problem. My experience with Origin product and services is extremely good. I strongly recommend to go for this company and its products.

Mr. Gunjan Mehta (Senior Research Fellow) @ IIT, Mumbai - Research & Development

Both the dehumidifiers are in working conditions and are maintaining the relative humidity of the lab perfectly.

Pradnya Torkar @ Foundation for Medical Research

Chemical Physics lab in our Department of Chemistry, IIT Bombay is mainly involved in the study of gas phase reactions. In our experiments, we require optimum temperature and humidity conditions for good experimental results. The humidity required is 40 - 50% which is met by the use of Origin dehumidifiers. The company gives free servicing and is very helpful in attending to our needs immediately. The response of the company is extremely good and satisfying.

Sohidul Islam Mondal @ Department of Chemistry, IIT - R & D

We are using this dehumidifier for Lithium batteries. This is working fine with us. We needed RH 45 - 55% and this is meeting our requirement. The service person did his job excellently and quite co-operative. We would like to see you regularly.

Prof. Mukhopadhyay @ ME & MS Department, IIT Bombay - R & D

It is to be declared that room humidifier model NH 809 and NH 900, make Novita and room dehumidifier model ND 316, make Novita being used in our laboratory since last 5 months (24th February to 13th June 2015). These are found working satisfactory.

Sarojkumar @ Dy. Quality Manager, Orbital Infrastructure Consultancy & Research Pvt. Ltd.

Dehumidifiers for Indoor Swimming Pools

Recreational Spaces are in great demand given the unabated urbanization that has led to shortage in quality spaces to unwind and relax.

Pool areas – especially indoor swimming pools run a high risk of having accumulated moisture – This moisture if not removed will slowly corrode & eat into your valuable adjoining the pool area and cause widespread water damage. Dehumidifiers prevent condensation on walls and ceilings, they also prevent black spots and fungal growth on wall and ceiling surface all of which is very common in pool areas due to high humidity levels. Portable dehumidifiers sense and suck out this excess moisture ensuring a healthy and dry environment in the indoor pool areas.

Dehumidifiers for Gyms, Dance Studios and Yoga Centers

Exercising is a major part of our lives these days and plays a very important role in it too. High humidity levels in fitness centers is a cause of concern. Moisture build up from sweat during workouts is a continuous contributing factor to adding the humidity in the room. This moisture also seeps into workout mats. High humidity levels in the room cause a stuffy and uncomfortable environment, also leads to mold and mildew build up, bacterial growth and corrodes equipment's and drastically reduces the life of fitness equipment's.

Dehumidifiers maintain ideal and consistent humidity levels. Dehumidifiers effectively perform and function to eliminate condensation, prevent mold, bacterial growth and bad odor. Dehumidifiers protect fitness equipment’s from moisture damage too.

Dehumidifiers provide a comfortable indoor setting which enhances the overall experience in the facility ensuring happy clients and healthy environment.

Dehumidifiers for Spa and Salons

Spa's and beauty salons try to recreate a relaxing atmosphere for its guests. There is a high level of activity in spa’s and beauty salons and varying people density causes the humidity in these areas to fluctuate very widely.

In various treatments, guests are exposed to high humidity as part of therapy , treatments also use steam to treat skin and body. Steam generates high humidity in enclosed spaces which gets trapped and causes airborne allergens, damp interiors and musty odor which has a direct impact in the overall guest experience. Dehumidifiers protect the interiors from dampness, dehumidifiers also prevent fungal growth and minimize the growth of airborne bacteria. Portable dehumidifiers ensure controlled moisture levels throughout which restrict musty odor from occurring and provide a hygienic indoor space which enhances the overall guest experience and provides a fresh and dry interior which ensure true comfort for the guests.